Ferroelectrics for Energy Applications

Brendan Hanrahan in the Pyroelectric Testing Lab at the U.S. Army Research Laboratory

Brendan Hanrahan in the Pyroelectric Testing Lab at the U.S. Army Research Laboratory

I am currently working on the development of new portable power systems towards military and consumer applications. Pyroelectric materials enable heat-to-electricity conversion schemes due to the unique relationship between polarization, temperature, and electric field in these materials. Their efficiency can be improved by manipulating the material properties and designing conversion systems that are tuned to specific heat sources. In the future, miniature electric generators could rely on this type of generation system.

I have decided to go more in-depth on this work so head over to Pyroelectric Energy

I have decided to go more in-depth on this work so head over to Pyroelectric Energy

Bioinspired and Biomimetic Devices

Photograph of an artificial Pacinian Corpuscle

Plants and animals have capabilities honed from millions of years of evolution. Humans now possess the creativity, technology, (and overconfidence) to try to mimic some of the functionality exhibited in nature. For example, the pacinian corpuscle senses vibration down to 10 nm (!) across the mammal kingdom using an ellipsoid cell with concentrically alternating mechanical properties for filtering. We made an artificial one using soft materials and liquid metal (pictured).

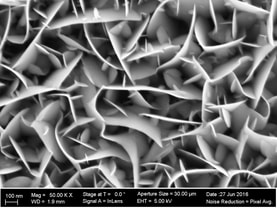

Nanostructured Iridium Oxide (NIrOx)

SEM Image of sputtered IrO2 film

Iridium metal and its oxides, which have been brought to earth from space, have some amazing properties. By reactive sputtering in oxygen plasmas, we grow ultra-high surface area, light absorbing, catalytic Iridium Oxide for numerous energy applications. We have also demonstrated robust processability for the nanostructured films (image left).

Microtribology (pre-2013)

My Ph.D. in Materials Science and Engineering focused on studying the tribology (friction, lubrication, and wear) of micro-scale bearings. Despite being studied since Leonardo Da Vinci, this work found some new aspects of rolling friction unique to small size-scales.

This work has given me experience in microfabrication, device design and modeling, materials characterization, process development, packaging, software development, diagnostics and reliability, and much more...

Project website: http://www.ece.umd.edu/MEMS/projects/microball.html

(Left: feature on Microball Bearing technology in Mechanical Engineering)

This work has given me experience in microfabrication, device design and modeling, materials characterization, process development, packaging, software development, diagnostics and reliability, and much more...

Project website: http://www.ece.umd.edu/MEMS/projects/microball.html

(Left: feature on Microball Bearing technology in Mechanical Engineering)

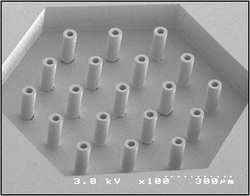

Electrospray (pre-2013 and occasionally as-needed)

As a full time Materials Engineer at the US Army Research Lab, I have been focused on developing low overhead, small-scale fuel-delivery systems for chemical-to-electrical energy conversion schemes. These methodologies include electrospray, vaporization, and related technologies.

Electrospray can also be used for the uniform deposition of nanomaterials. We have shown carbon nanotube supercapacitor electrodes deposited in this manner. Electrospray also has potential for spray cooling applications.

(multiplexed electrospray nozzle array fabricated in silicon)

Electrospray can also be used for the uniform deposition of nanomaterials. We have shown carbon nanotube supercapacitor electrodes deposited in this manner. Electrospray also has potential for spray cooling applications.

(multiplexed electrospray nozzle array fabricated in silicon)